Candy Making Equipment

In-line And Countertops Machine

Our Candy making machine is for heavy to light candy production. The machine is controlled by a full servo motor and operated by touch screen ECU. The pouring amount and pouring speed. Is easy to adjust and control with high degree of automation. Our Candy pouring machines can produce candy of various materials and shapes, including soft candy, toffee, hard candy, chocolate candy, lollipop and other candy of various shapes and flavors. Our Candy machines are suitable for various scenarios in the candy industry, including candy manufacturing, candy shops, candy production factories, etc.

countertop

30-60 pieces permanent 130-230 pounds per hour 220V/50Hz 5.5hp 10 head 3.5ft/3ft 3ft 250 pounds

in line

20-35 pieces permanent 80-350 pounds per hour 220v/50Hz 1.5hp 20 head 2.5ft/2ft/4.5ft

700 Pounds

1 Minimum injection capacity of 0.2g, maximum unlimited

2 The hopper adopts electric heating, which heats up quickly and saves more energy

3 With cleaning mode, automatic cleaning, solve the problem of sticky sugar not easy to clean after use

4 The PLC of the desktop candy machine has data memory function, which can store two different sets of process data

5 The conveyor of the desktop candy pouring machine is equipped with single person and double person modes to improve production efficiency

6 The switch of the vertical candy pouring machine has a water filtering function, extending its service life

Candy Coating Machine

Our candy coating machine is great for all kinds of products, nuts, raisins, gummy, hard, candy we have heavy to light industrial, and also a countertop model The candy-coated with a shiny polished surface can prevent oxidation and moisture The candy coating machine has wide usages which can produce a variety of delicious treats. The product centers include dried fruits, seeds, nuts, toffees, caramels, biscuits, extruded products, chewing gums and chewy candies etc. The product coatings include syrup, sucrose, dextrose, polyol and icing sugar etc. The candy coating machines are suitable for confectionary plants, snack plants and other food processing plants. Features 1. This coating machine is used for food industry. 2. This coating machine is used for rolling and heating beans and edible nuts seeds and candies. 3. This coating machine can be used to polish chocolates and nuts of various shapes such as cylinders, oblate, to make their surfaces well lustrous and colored.

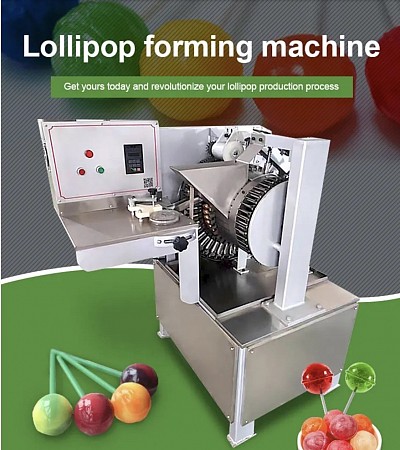

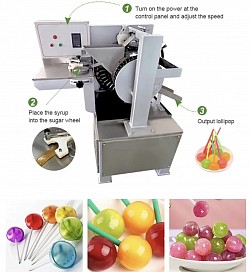

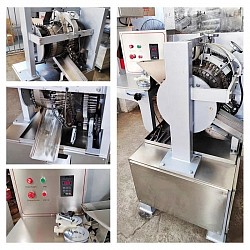

lollipop Candy Making Machine

Lollipop machine

Our Lollipop forming machines can be widely used in various lollipop manufacturing scenarios to improve production efficiency and quality and reduce labor cost It can be used alone or in combination. It is an ideal peace of equipment for companies in the candy

Industry

1. Lollipop forming machine is used to produce spherical lollipop. It can insert plastic sticks, bamboo sticks, whistling sticks, etc.

2. Lollipop forming machine is suitable for all candy manufacturers of all sizes

1. High degree of automation, reduce manpower.

2. User friendly, easy to learn how to use the machine quickly.

3. Produce lollipop of various flavors to meet the needs of specific customers.

3.5ft *3ft*4ft 220V 2hp candy weight 6 18g 220-660 pounds per hour machine weight 1300 pounds

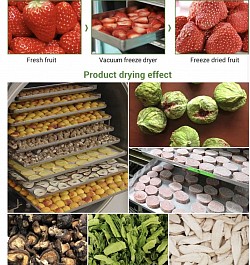

Freeze Drying System

The vacuum freeze dryer for fruits vegetables is an advanced drying equipment, vacuum freezi drying is to freeze the fresh material under low temperature, under the vacuum low temperatur heat it, make the frozen ice in the material turn into vapour directly by sublimation, and collecte by condensator. This method to reach fast drying, keep the shape, nutrition of the material in th max degree.

Working principle

Vacuum freeze drying machine, is a kind of dehydrator that drying the products in vacuum condition, also is one of the best recognized way to drying products.

Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase...so freeze-drying causes less damage to the substance than other dehydration methods using higher temperatures.

Contact us for more details details